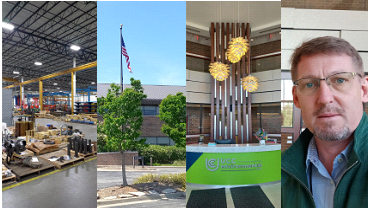

In response to UCC Environmental visit to DKE office in Hanoi in spring 2023, from 11 to 13 May 2023, DKE visited UCC Environmental in Waukegan, USA. The purpose of the visit is to strengthen cooperation between UCC and DKE by presenting DKE services within MEP global projects to other UCC divisions such as WWT EPC and Part & Technologies.